Considering how digital technology is transforming construction and manufacturing

Q&A: Digital transformation in the manufacturing and construction sectors

It’s no secret that Britain’s manufacturing sector has been hamstrung by a longstanding productivity problem, or that the country is experiencing a housing crisis, with 1.5 million new homes needed over the next five years.

But both construction and manufacturing are undergoing something of a technology-driven transformation, which holds the potential to support each sector’s ongoing growth and resilience.

With this in mind, we sat down with Justin Matthews, a London-based Partner in our Financial Advisory team and Martyn Pullin, a Partner in our Restructuring Advisory team based in Teesside to get their insights.

How are businesses in each sector using digital transformation effectively and how is this changing?

Justin Matthews: “Digital construction tools like Building Information Modelling (BIM) and Computer-Aided Design (CAD) software aren’t new, but given the huge productivity benefits they can enable, uptake has perhaps been surprisingly slow.

“Starting from a shared 3D digital model of a building not only supports commissioning and sign off, it means contractors can tender for work more accurately and, once on site, all trades can provide real time updates on their progress.

“It makes the whole construction process more accurate and efficient, and means project managers can keep a close eye on costs and timings, reducing the potential for expensive and inconvenient delays.

“While Modern Methods of Construction (MMC), like offsite and modular construction, may be struggling to fulfil its potential, it must surely have a role to play in helping the ambitious housing targets laid out by the new government.

“These targets, as well as falling inflation, should give greater certainty to contractors and support investment in a sector that can generate massive time efficiencies.

“This would help MMC companies generate a secure pipeline of work and help them achieve the economies of scale that can in turn enable them to reduce their prices.”

Martyn Pullin: “It’s heartening to see so many UK manufacturers recognising and realising the benefits of digitisation.

“According to Make UK, 80% of manufacturers will have implemented digital technologies in their business by 2025.

“It’s important because we need this kind of investment in order to remain globally competitive and improve UK productivity which lags behind other big OECD economies.

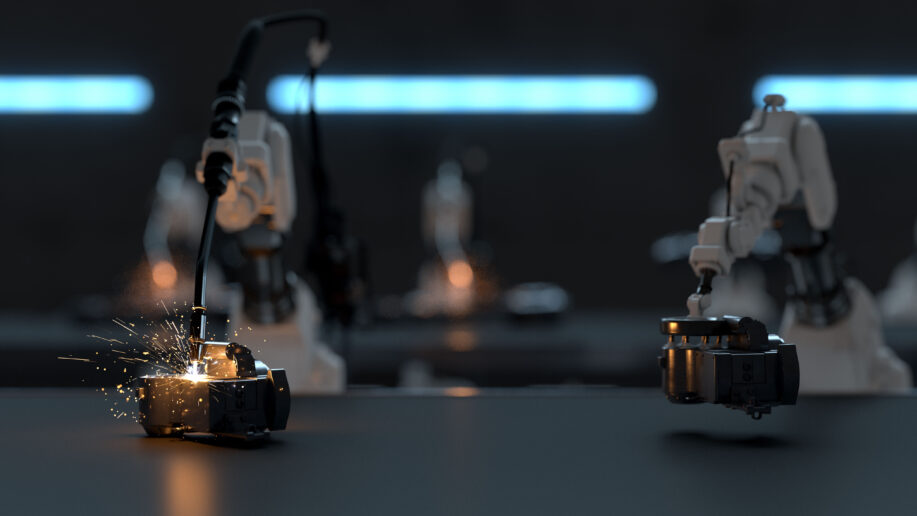

“The application of technologies including Artificial Intelligence (AI), machine learning, robotics and automation can enable data-driven efficiencies that save time, reduce waste and cut costs in all kinds of processes.

“It can also help firms overcome the skills shortages that have proved so persistent.

“3D printing, for example, is being used to create complex components on site, shortening supply chains and supporting new product development.”

Why is digital transformation useful – particularly from the perspective of a business’ resilience?

Martyn Pullin: “A huge part of AI’s value is in enabling manufacturers to analyse large amounts of data, which can be used to incrementally optimise processes.

“By digitising everything from order books to machine servicing logs, quality control standards and delivery schedules, AI can spot potential logjams and opportunities for efficiencies.

“And predictive maintenance can identify potential problems on assembly lines before they happen, avoiding costly downtime.

“It’s this increased visibility over operations and supply chains that can naturally help manufacturers to better anticipate and manage risks, making a business more resilient in the process.”

Justin Matthews: “Construction projects typically involve multiple teams of different trades, overseen by a single project manager.

“That’s often a recipe for costly mistakes and re-builds, so anything that can provide more certainty for all stakeholders is a step forward.

“By building immersive virtual versions of buildings before construction starts – known as digital twins – everyone has full visibility and can interrogate every aspect of the design and budget.

“It enables improved collaboration, better decision making, accurate procurement and means anyone can flag any potential problems at the earliest stage.

“And if any changes are needed, they can be tested in the virtual world before being implemented.

“It means the cost of any project can be accurately estimated.

“Taken together, all these benefits mean the initial investment in digital twin technology can easily be justified.”

What are some of the blockers to progress that might need to be overcome?

Justin Matthews: “Recruitment and retention is a longstanding issue for the sector.

“The kind of tech skills that the construction firms want are also in demand across the economy, making recruitment even more competitive.

“But the sector isn’t only struggling to recruit young people, it’s getting harder to hang on to more experienced, senior colleagues too.

“The sector is looking to drive more interest in construction as a career, which means creating real opportunities for career development through training and mentoring.

“The new government has some ambitious plans around infrastructure and housing, which builders flagged as important in our recent construction report, which will hopefully boost the sector’s profile and create more certainty.”

Martyn Pullin: “British manufacturing’s progress to improve productivity has been held back by a lack of investment.

“Our manufacturing report last year found firms holding back investment because of economic uncertainty (52%) and because borrowing was too expensive (30%).

“But, with interest rates now appearing to be on the way down – albeit slowly – and a new government in place that has committed to launching a modern industrial strategy, it looks like the conditions for investment, including in areas like digital transformation, are improving.”